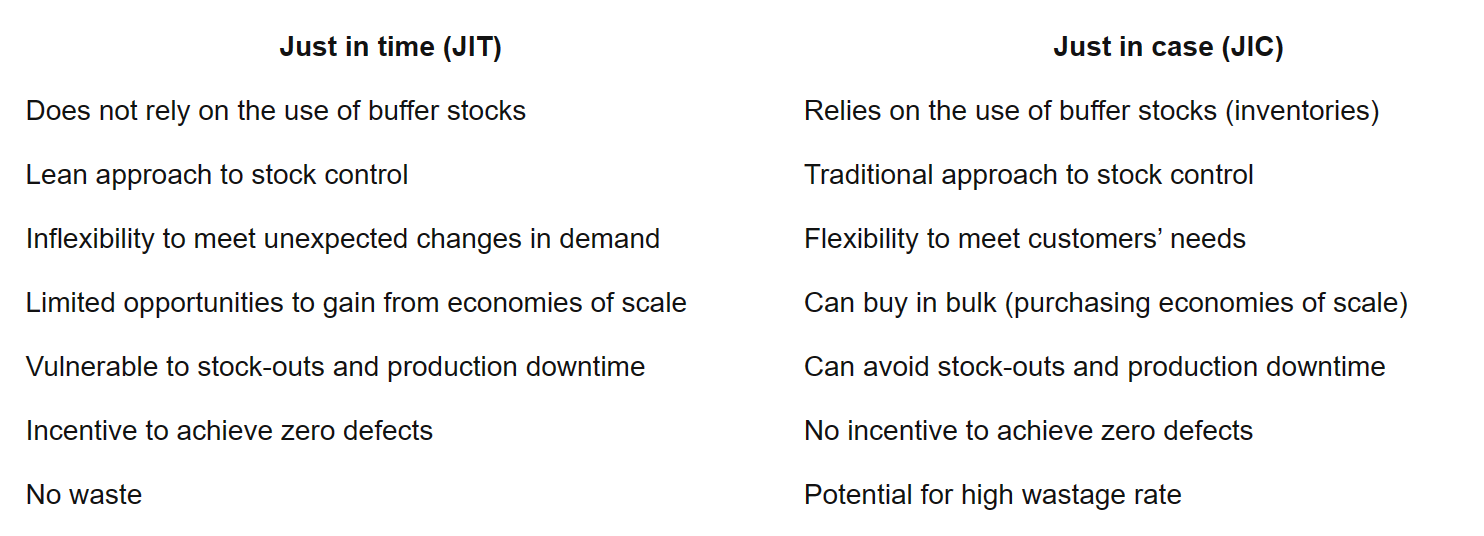

JIT

- lean production method of stock control

- deliveries of stock just in time for them to be used in production process

- removes cost of buffer stocks

- eliminates storage, reduces insurance, and maintenance

- continuous improvement, difficult to manage for big organizations

- stock is delivered right after required for production

- working capital is not tied up in inventory, which might not be liquid

STORAGE COSTS

- storage

- insurance

- wastage

- security (for theft prevention)

- maintenance

- damage

advantages

- no buffer stocks

- minimal wastage

- improve liquidity

- improve competitiveness due to lower costs of stock management + improved product quality disadvantages

- harder to get economies of scale

- tech to manage stock is expensive

- relies on 3rd parties

- inflexible if demand increases suddenly

JIC

- have buffer stocks so you always have enough in case of changing demand

- meet unexpected orders quickly

- suitable for durables, not perishables

- power tools, batteries, torches, nails, pens, greeting cards, lego toys, toothpicks advantages

- buffer stocks are flexible for sudden changes in demand

- production can continue even if suppliers give stock late (because of buffer stock)

- economies of scale when you buy stuff in bulk

- customers don’t have to wait for product disadvantages

- costs ⇒ insurance and maintenance + security of stocks

- subject to damage or theft

- stockpiling reduces cash flow + working capital

- suppliers can charge high prices for urgent deliveries of stock

- unsuitable for perishable products (i.e. food)